The fascination of tunnel construction

The fascination of tunnel boring with compact components

Tunnel construction is one of the most fascinating but also most difficult tasks in the construction industry. There are direct dependencies between the permanent tunnel structure, the excavation of the required tunnel cavity, and the rock to be traversed. The surrounding rock is also used for its load-bearing effect, thus becoming a building material. The excavation of the tunnel cavity usually takes place in rock formations that, due to their origin, are layered differently, folded, and exposed to weathering and water ingress in various ways. The subsoil has a wide range of material properties and characteristics, which must be taken into account in the construction methods and, above all, in the safety measures.

“Tunnel construction combines theory and practice to form a unique branch of civil engineering. Today, tunnel construction is largely carried out by civil engineers, but it should be noted that knowledge of statics and solid construction alone is not sufficient. Geology, geomechanics, mechanical engineering, and, in particular, construction process engineering are equally important.”

Precise surveying methods using satellites enable planners to stay on course.

Tunnel builders can encounter a wide variety of subsoils. However, they usually drill and blast rock. Advancing into the depths has developed into a relatively safe high-tech undertaking. Today, gigantic tunnel boring machines, often operated by a single expert, do the hard work. With an advance rate of up to 40 meters per day, they work their way through rock or silt almost independently.

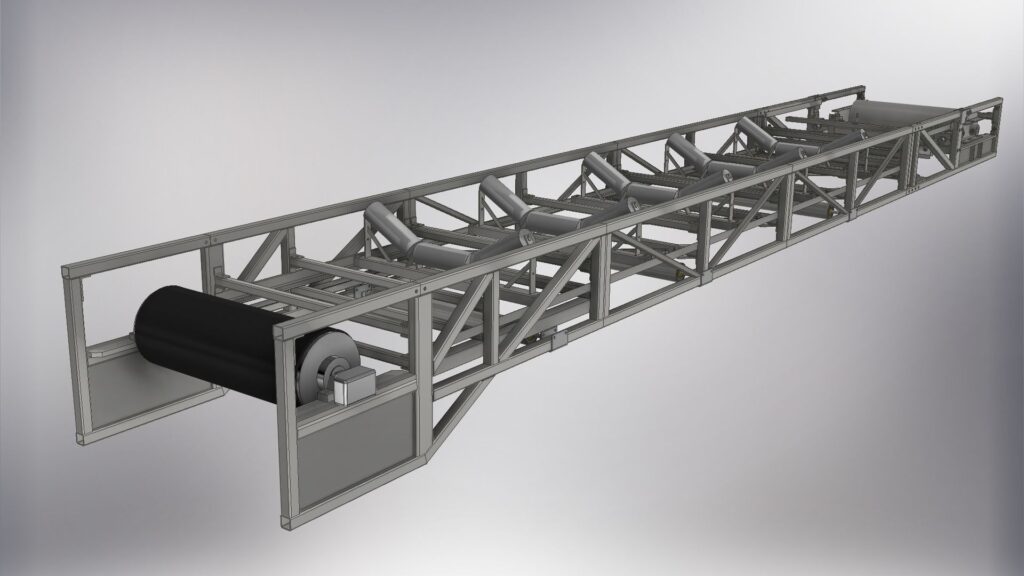

At the same time, they secure the tunnel walls with steel arches and line them with a layer of concrete. Parallel drainage systems divert water from the mountain. However, blasting is still used in some cases. Several successful projects have shown that these conveyor belt systems for removing rock are very suitable and cost-effective alternatives to rail-bound spoil cars, as they enable very good performance due to high system availability, high operational reliability, and high load-bearing capacity.